Machine Park

Thanks to the wide developed and technically advanced machine park, as well as to our long-term experience in the field of glass processing, we are able to meet even the most demanding projects of our clients.

Our machine park includes the following:

CUTTING TABLE CNC /x1/

The capabilities of this machine allow us to cut both rectilinear and curved glass (shapes). The cutting table has a double-sided automatic glass charger, thanks to which we are able to immediately change the settings of the machine to adjust it to a different thickness of glass or type.

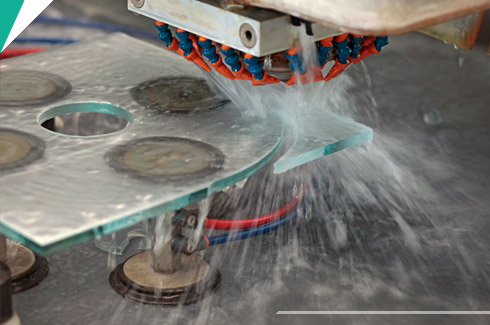

WATER JET (WATER CUTTING DEVICE) /x1/

With the help of this machine we can cut openings of any shapes in the glass. Water pressure reaches about 4000 bars, thus, we can cut material of thickness of up to 25 cm. The producer of this device is a well-known Swedish WJS company, which means that we maintain strict tolerances for cut holes.

CNC CENTER /x1/

This machine allows us to process glass of different shapes by operations such as grinding, polishing, drilling, milling and also to keep a very high quality at the same time.

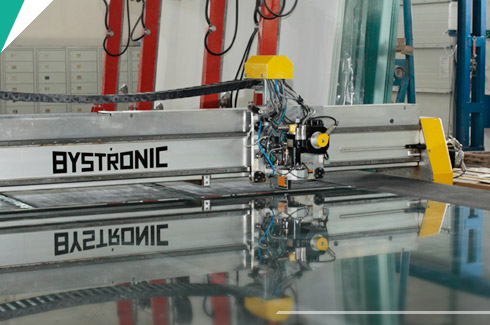

BYSTRONIC FULL AUTOMATIC CNC MACHINE TO GRIND EDGES OF DIFFERENT SHAPES

This machine allows us to process very large amounts of glass and to maintain high quality of processed edges as well as dimensional tolerances.

CNC DRILL /x5/

All our glass drilling machines are numerically controlled with automatic mobile work tables. Thanks to this solution, we eliminate errors with the positioning of openings in the glass, and as a result, we meet the strict requirements of our customers, and our products are replicable within mass production.

CRANE /x1/

With our crane, we can quickly and safely unload glass loads, as well as load glass on the cutting table.

GRINDING AND POLISHING LINE FOR C AND F EDGE TYPES /X2/

These lines allow us to process glass in large quantities, but only in square or rectangular shapes.

EDGE GRINDING MACHINE /x10/

We own many machines with various possibilities for grinding and milling glass of various shapes and sizes.

GLASS BENDING MACHINE /x3/

We have three different glass bending devices suitable for arc bending, spherical one, and as well, for multi-plane bending.

SCREEN PRINTING LINES /x4/

We have four different screen printing lines, thanks to which we can print glass of various sizes. Glass after printing is automatically placed in IR tunnels, in which the paint is heated and dried. Thanks to this solution, the print quality is flawless. At Szlif Glass, we use only water enamels that are environmentally friendly.

SANDBLASTING LINE /x1/

Our sandblasting line is a high-performance machine for glass matting and our matt surfaces are of a very high quality.

WASHING MACHINES /x7/

Our horizontal washers enable us to wash the glass immediately after each processing cycle.

TEMPERING FURNACE /2x/

We have two furnaces for flat glass tempering. The smaller furnace allows us to temper technical glass of dimensions up to 40 x 40mm. The second furnace, larger, allows hardening of much larger elements, because of the chamber dimensions: 1200 x 4000 mm.

A very important feature of our production is that we can temper glass of thickness starting from 2.85 mm.